Directory navigation

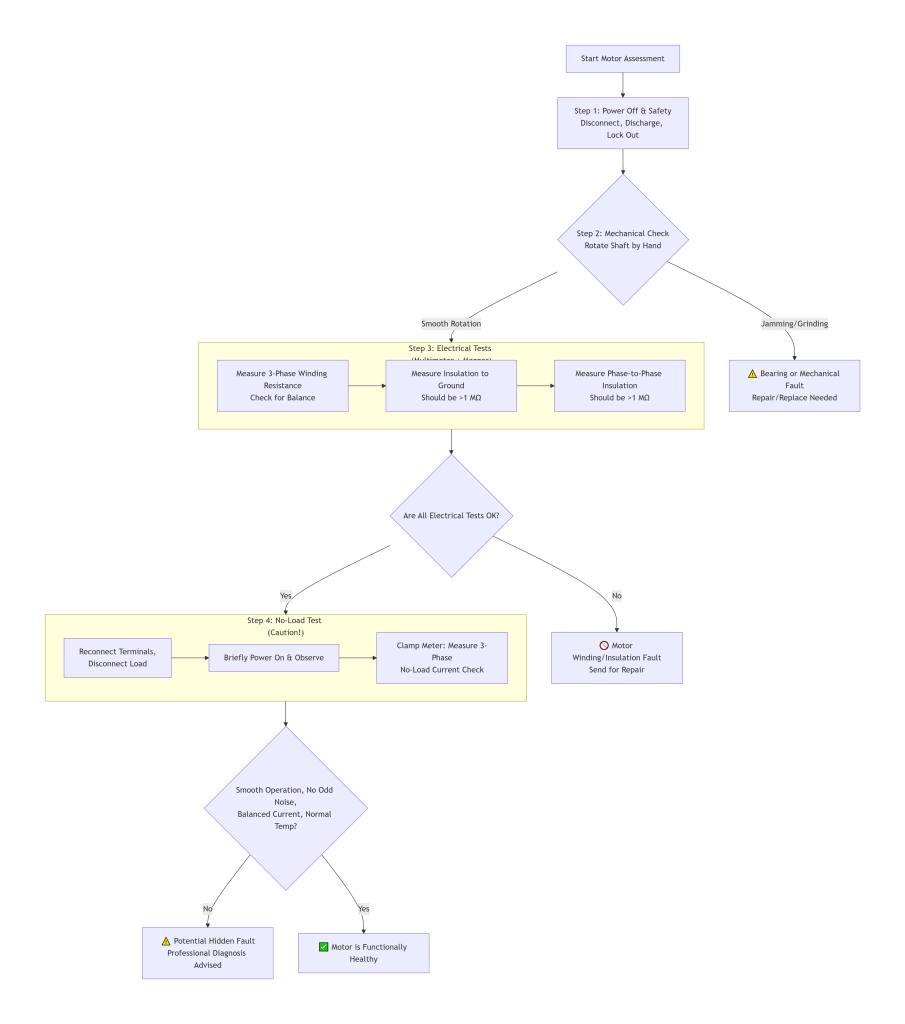

- Part 1: Power-Off Tests (Safest & First Step)

- 1. Visual & Mechanical Inspection

- 2. Measuring Winding Resistance (Using a Multimeter)

- 3. Measuring Insulation Resistance (Using a Megohmmeter/”Megger,” 500V range recommended)

- 4. Checking Phase-to-Phase Insulation

- Part 2: Power-On Tests (Perform only after all power-off tests are normal. Caution!)

- 5. No-Load Running Test

How to Measure the Health of a Three-Phase Motor

A healthy three-phase motor should have balanced readings across all three phases for winding resistance, insulation to ground, and operating current.

Part 1: Power-Off Tests (Safest & First Step)

1. Visual & Mechanical Inspection

- Visual Check: Look for signs of burning, cracking, deformation, or water damage.

- Manual Rotation: Disconnect power and turn the motor shaft by hand. It should rotate smoothly without binding, grinding noises, or the feeling of the rotor rubbing against the stator (a sign of bearing failure).

2. Measuring Winding Resistance (Using a Multimeter)

- Purpose: Check for open windings or severe turn-to-turn shorts.

- Steps:

- Remove all connecting links in the motor terminal box, isolating the three windings (U1-U2, V1-V2, W1-W2).

- Set your multimeter to the resistance (Ohms) function, on a low range.

- Measure the DC resistance between each pair of terminals: U1-U2, V1-V2, W1-W2.

- Interpretation:

- Normal: All three resistance values are very close (balanced), typically within ±2% of each other (e.g., 1.50Ω, 1.52Ω, 1.49Ω).

- Abnormal:

- Infinite resistance (OL) on one phase: That winding is open.

- Significantly lower resistance on one phase: Likely a turn-to-turn short in that winding.

- Unbalanced resistance beyond tolerance: Indicates winding damage.

3. Measuring Insulation Resistance (Using a Megohmmeter/”Megger,” 500V range recommended)

- Purpose: Check the insulation between the windings and the motor frame (ground) to prevent leakage and electric shock.

- Steps:

- Verify the Megger is functional (perform an open/short test).

- Connect one lead (L) to one motor phase (e.g., U1) and the other lead (E) to a clean, unpainted spot on the motor frame.

- Crank the handle at a steady speed (~120 RPM) and note the stable insulation resistance reading.

- Repeat for all three phases (U, V, W) to ground.

- Interpretation:

- Good: Insulation resistance > 1 Megohm (MΩ). For new or refurbished motors, it should be much higher (often > 5 MΩ or even > 100 MΩ).

- Failed/Damaged: Insulation resistance < 0.5 MΩ indicates moisture or deterioration. A reading near zero indicates a ground fault (winding shorted to frame), which is dangerous.

4. Checking Phase-to-Phase Insulation

- Purpose: Ensure there is no short circuit between different windings.

- Steps:

- Keep the terminal links disconnected.

- Connect the Megger leads between two different phases (e.g., U1 and V1).

- Crank and measure the insulation resistance between U-V, V-W, and W-U.

- Interpretation: Same as above. Resistance should be > 1 MΩ. A low reading indicates a phase-to-phase short.

Part 2: Power-On Tests (Perform only after all power-off tests are normal. Caution!)

5. No-Load Running Test

- Prerequisite: All previous tests passed and the shaft rotates freely by hand.

- Steps:

- Reconnect the terminals correctly (in Star/Y or Delta/Δ as per the nameplate).

- Ensure the motor is uncoupled from any load (it will run idle).

- Apply power briefly to start the motor.

- Observation & Interpretation:

- Start & Run: Should start smoothly, reach normal speed, and run quietly without unusual noise (scraping, loud humming).

- Measure No-Load Current: Use a clamp meter on each of the three power leads.

- Normal: All three no-load currents are balanced and typically between 30% – 60% of the motor’s rated full-load current (lower percentage for larger motors).

- Abnormal:

- Unbalanced currents: Suggests winding issues (turn shorts), incorrect connection, or power supply problems.

- Excessively high no-load current: May indicate an uneven air gap (worn bearings), damaged core, or high voltage.

- Touch & Smell: After running for a few minutes, disconnect power and touch the motor casing. It should be warm, not hot, and uniform. Smell for any burnt insulation odor.