Home>Products>cottonseed oil machine>Good price batch oil refinery /olive oil refiney plant /crude cooking oil refinery machine

Good price batch oil refinery /olive oil refiney plant /crude cooking oil refinery machine

- cottonseed oil machine

cottonseed oil machine

- China

- ISO,CE

- One set Good price batch oil refinery /olive oil refiney plant /crude cooking oil refinery machine

- [email protected]

- refer to capacity

- contact with us

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 174

Microwave dryer dehydration sterilization machineChina

-

Microwave dryer dehydration sterilization machine2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Microwave dryer dehydration sterilization machine2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

Good price batch oil refinery /olive oil refiney plant /crude cooking oil refinery machine

Product Description

Crude oil refinery equipment

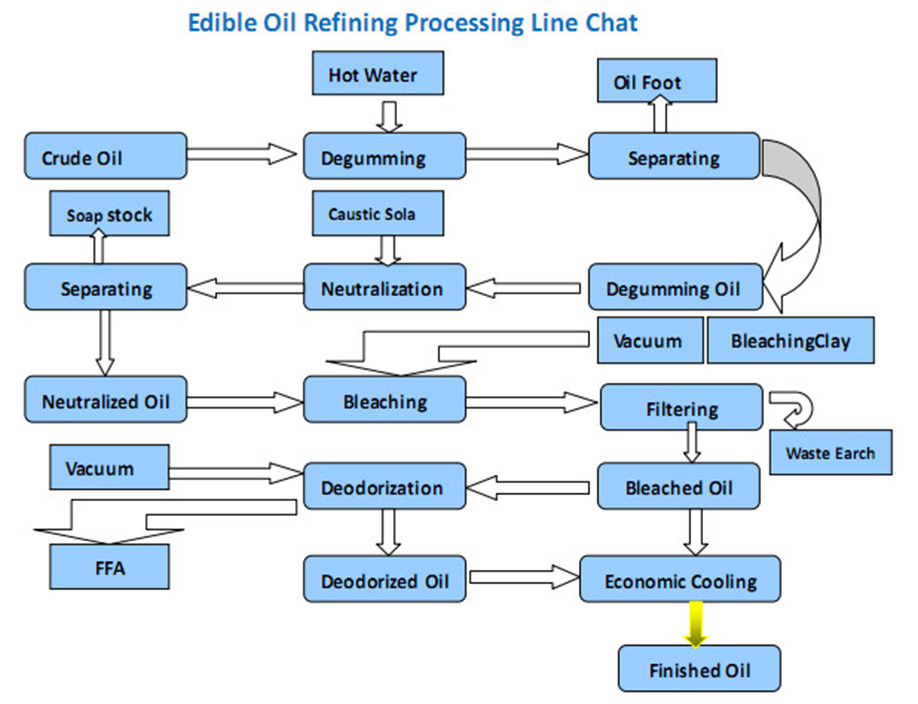

1) Edible / Vegetable oil refining is a step by step process. Refining of oil removes phospholipids, pigments, off-flavor, free fatty acids, and other impurities. The entire oil refining plant process comprises degumming, neutralization, bleaching, deodorizaiton ,and winterization/dewaxing (optional).

2)Refining crude oil: palm oil, soybean oil,peanut oil, mustard seed oil, cottonseed oil, sunflower seed oil, olive oil , rice bran oil, safflower seed oil, corn germ oil, camellia seed oil, etc

Main equipmant

1) Refining section: used to P-acid de-gumming, alkali refining de-acid and water rinsing.

(2) Decoloring section: used to remove off pigments, bleaching oils and grease dehydrate.

(3) Deodorizing section: to remove off the odor components in oil.

(4) Dewax: used to remove off the wax in the oil, in order to get the high quality oil.

(5) Heat-transfer oil stove: supply each device production needing heat energy, temperature reach above 280°C.

(6) Steam generator: produce the needing steam for de-odoring and distillation.

(7) Good price batch oil refinery /olive oil refiney plant /crude cooking oil refinery machine pump: supply needing Good price batch oil refinery /olive oil refiney plant /crude cooking oil refinery machine for dehydrate, de-color, de-odor. Good price batch oil refinery /olive oil refiney plant /crude cooking oil refinery machine degree can reach above 755mm Hg.

(8) Press filter: filter clay, filter out clear oil.

(9) Air compressor: blow dry bleached clay, blow empty the leftover oil in the press filter.

Main process of oil refinery

Neutralization Process :The crude oil is pumped to Neutralizer from oil mill or storage tank & first it is treated with weak solution of phosphoric acid or other suitable degumming agent for removing gums. Neutralizer is used remove the Free Fatty Acids (FFA) by adding caustic soda. Oil is heated up to about 60°C by heating coils and oil is stirred by the stirrer. The chemical reaction between free fatty acid and caustic soda forms the soap stock. This soap stock is allowed to settle down in the neutralizer from where it is collected into the soap pans. The oil is then washed with hot water to remove traces of soap particles and free alkali.

Bleaching Process :In the bleaching process, excess color from the oil is removed. Neutralized oil is heated in the bleacher vessel to remove excess moisture and thereafter it is treated with a measured quantity of bleaching earth and activated carbon. Nextly oil passes through a filter to separate bleach earth and bleached oil. Oil obtained after bleaching process is light in color and has good golden type appearance.

Deodorization / De-acidification Process :The deodorization process removes odor from the oil to improve the quality and self-life of the oil. The clean bleached oil is heated in the deodorizer to remove all the odiferous material such as phenols, ketones, tocopherols, aldehydes etc. The oil is heated in the deodorizer above 110°C through thermic fluid coils and then live steam is given to the oil from the bottom steam nozzles and temperature of oil is raised up to 200 to 220°C through thermic fluid coils. Entire process is done under high Good price batch oil refinery /olive oil refiney plant /crude cooking oil refinery machine. Thus smell is removed from the oil in the deodorizer.

Company Information

Zhengzhou Good price batch oil refinery /olive oil refiney plant /crude cooking oil refinery machine Indutech Machinery Co., ltd (hereafter referred to as "Good price batch oil refinery /olive oil refiney plant /crude cooking oil refinery machine") is a joint-stock machinery manufacturing enterprise, integrating industrial scientific research, production and marketing. The company is located in the Industry Area Zone of Zhengzhou, China.

1.Pre-sale services:

1) Selecting equipment type;

2) Designing and fabricating the products in accordance with the special requirements of the clients;

3) Training technical personnel for our clients;

4) Providing construction and technology consultations or working out proper construction schemes for those new, special or difficult projects.

2.Services provided during the sale:

Respect our clients; present the clients with ease, relaxation and a surprise; devote ourselves to improve the total value of our clients.

1) Checking products acceptance ahead of delivery;

2) Introducing the service system to our clients.

3. After-sale services:

Improve the added value of our products, and let the clients free from the using troubles:

1) Assisting the clients preparing for the first construction scheme;

2) Installing and testing the equipments;

3) Training the first-line operators on site;

4) Examining the equipment regularly;

5) Taking the initiatives to eliminate the failure(s) rapidly at site;

6) Distributing the guarantee fittings door-to-door;

7) Providing technical exchanging;

8) Providing maintenance for big item

Packaging & Shipping1.Waterproof packing with the international export standard by 20ft, 40ft, 40hp container.

2. Equipment Fittings, Electric Motor and Power Cabinet will be packed in Wooden Case or Iron Box. Other Equipment will be packed by Color-Stripes Plastic Cloth.

3. Or as per customer's requirements.

If you want to know more information , Pls to contact us

Tel: 0371 55933391 Fax: 0371 55919082

Contact Us

- Microwave dryer dehydration sterilization machine

- AddressBawang Road, Licheng District, Jinan City, Shandong Province

- Phone(Working Time)86-531-4897119

Related News

| Microwave Technology in Traditional Chinese Medicine Production |

Product Categories

- laboratory drying equipment

- chinese herb dehydration and sterilization

- chinese medicine herb drying equipment

- chemical powder drying equipment

- Microwave dryer and sterilization machine

- chinese medicine extraction machine

- paper dehydrator and sterilizer

- paperboard drying equipment

- microwave fast food heating machine

- latex products drying machine

- microwave oven tunnel machine

- Microwave roasting equipment

- microwave sterilizer equipment

- Oil seeds Processing Line

- soybean oil machine

- Sesame Oil machine

- coconut oil processing machine

- mustard oil machinery

- Shea Nut Oil machine

- Castor Oil machine

- Walnut Oil machine

- Corn Germ Oil machine

- Rapeseed Oil machine

- Rice Bran Oil machine

- microwave dryer equipment

- cottonseed oil machine

- Sunflower Oil machine

- Peanut Groundnut Oil machine

- Small Scale Oil Refining Line

- palm fruit machine

- solvent extraction machine

- Full Continuous Refining Line

- Biodiesel Machine

- flaxseed oil Machine

- camellia oil Machine

- moringa seed oil machine

- Complete oil production line

- Seed Hydraulic Press Machine

- Large Scale oil Machine

- Edible Oil Filling Line

- oil Pretreatment Equipment

- Oil Extraction Equipment

- puffed snack food machinery

- corn filling snack machinery

- Fish food machine

- Animal food machinery

- Fried Kurkure machine

- Fried cheetos machine

- Baked kurkure machine

- Baked cheetos machine

- Corn flakes Machinery

- Frying snacks machinery

- Nacho Chips machinery

- Corn Chips machinery

- Tortilla machine

- doritos machine

- bugles machine

- Soyabean protein machine

- Extrusion food machine

- Macaroni pasta machinery

- Nutritious artifical rice food machine

- Bread crumbs machine

- Nutritional powder machine

- Modified starch machine

- modify starch machine

- Potato Chip Machine

- rice cracker machine

- Biscuit Production Line

- Textured Soya Protein machine

- Instant Noodles Production Line

- Fried Wheat Flour Snacks Making Machine

- Nutrition Bar Making Machine

- snack Food Packing Machines

New oil extraction and refining plant made in China

New oil extraction and refining plant made in China Process Of Making Vegetable Oil

Process Of Making Vegetable Oil Soya Oil Manufacturing Process

Soya Oil Manufacturing Process new technology edible oil project

new technology edible oil project More 30 years experience peanut Oil Production Plant

More 30 years experience peanut Oil Production Plant